Trunnion ball valves

The Trunnion ball valve is recommended for any pressure class and its safe sealing can grant a high performance.

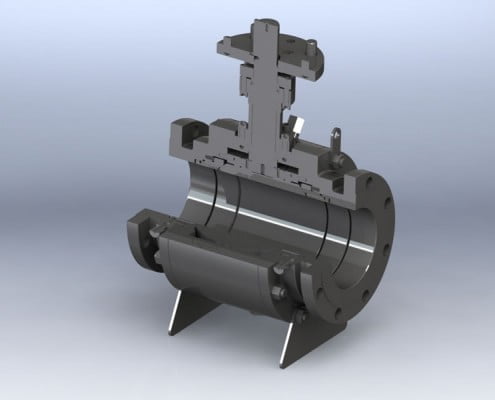

In the Trunnion design configuration, the ball is supported by bearing plates, held in position by the valve closures. This configuration allows to discharge any side loads on the valve body, enabling a smoother operation of the ball, minimizing the operating torque and reducing seat seal wear.

The operation of the valve is always on-off with 90° movement.

This configuration makes the valve suitable for handling by means of actuators.

The manual operation involves the use of levers or gears depending on the torques of the valve.

Independent floating spring loaded seats are always in contact with the ball to provide an effective tight seal. With the single piston effect design, there is an automatic body cavity release of over pressure to the line through the down stream seat.

The double piston effect design (available on request), maintains the sealing capacity of the valve even in the case of failure of the up stream seats. Body cavity over pressure in this case can be released through a relief valve to atmosphere. The tightness is assured by the piston effect acting on the seat, pressing it against the ball, once the valve is pressurized.

Pre-loading springs ensure the start-up of the valve.

It is also possible to provide the “metal-to-metal” ball seat seal, suitable for high temperatures and not filtered raw fluids, which otherwise, would damage the soft seats.

Main applications in the petrochemical field:

- Cryogenic service.

- Low temperature.

- Ambient temperature.

- High temperature.

- Corrosive fluids.

- High pressures.

These valves can be designed to meet with Customer’s requirements: for instance, they may be buried in the ground and made operable by the extensions.

Valves are built in any steel required by the Customer and defined in the data sheet according to the quotation request.

Trunnion ball valves produced by Etiovalves can be designed in accordance with following certifications:

- ISO (International Organization for standardization)

- PED (Pressure Equipment Directive)

- ATEX (ATmosphères EXplosibles)