Floating ball valves

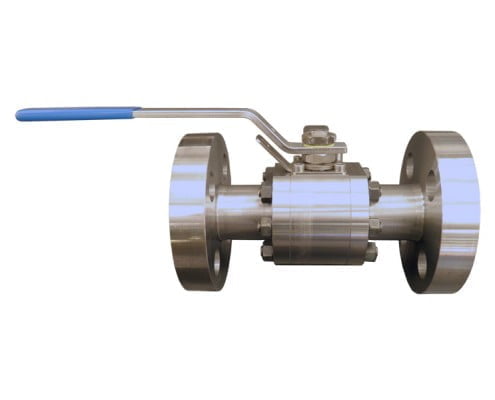

The Floating ball valve is recommended for relatively low-pressure classes, namely Class 150-300 to 20-50 bar, or for very small sizes combined with high pressures, such as ½ ”, namely Class 2500 430 bar; the strength of this type of valves is the excellent quality/price ratio because, at the same size and class, they are cheaper than the Trunnion type valves.

The operation of the valve is always on-off with 90° movement and the operation can be manual or implemented according to the requests.

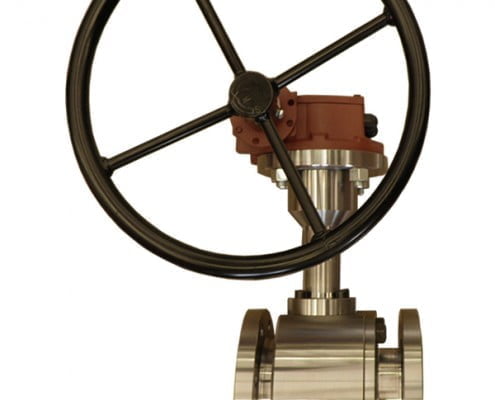

The manual operation involves the use of levers or gears depending on the torque figures of the valve.

The tightness of the valve is guaranteed by the floating ball, which, when pressurized, moves to the seat.

It is possible to provide the “metal-to-metal” ball seat seal, suitable for high temperatures and not filtered raw fluids, which otherwise, would damage the soft seats.

Main applications in the petrochemical field:

- Cryogenic service.

- Low temperature.

- Ambient temperature.

- High temperature.

- Corrosive fluids.

- Low pressures.

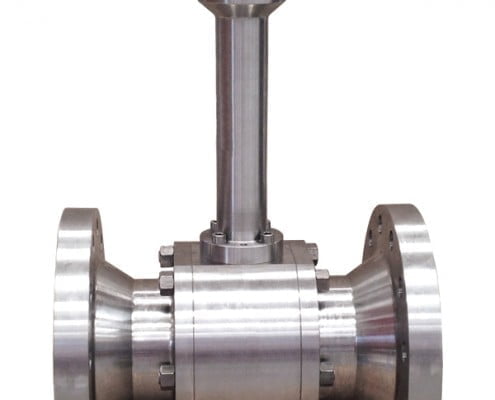

These valves can be designed to meet with Customer’s requirements: for instance, they may be buried in the ground and made operable by the extensions.

Valves are built in any steel required by the Customer and defined in the data sheet according to the quotation request.

Valves can also be equipped with devices such as limit switches, dead man lever etc.

Floating ball valves produced by Etiovalves can be designed in accordance with the following certifications:

- ISO (International Organization for standardization)

- PED (Pressure Equipment Directive)

- ATEX (ATmosphères EXplosibles)