Design

The technical department is constantly committed to investigate new solutions to the different operating conditions required by customers. Its goal is to comply with Customer’s requirements.

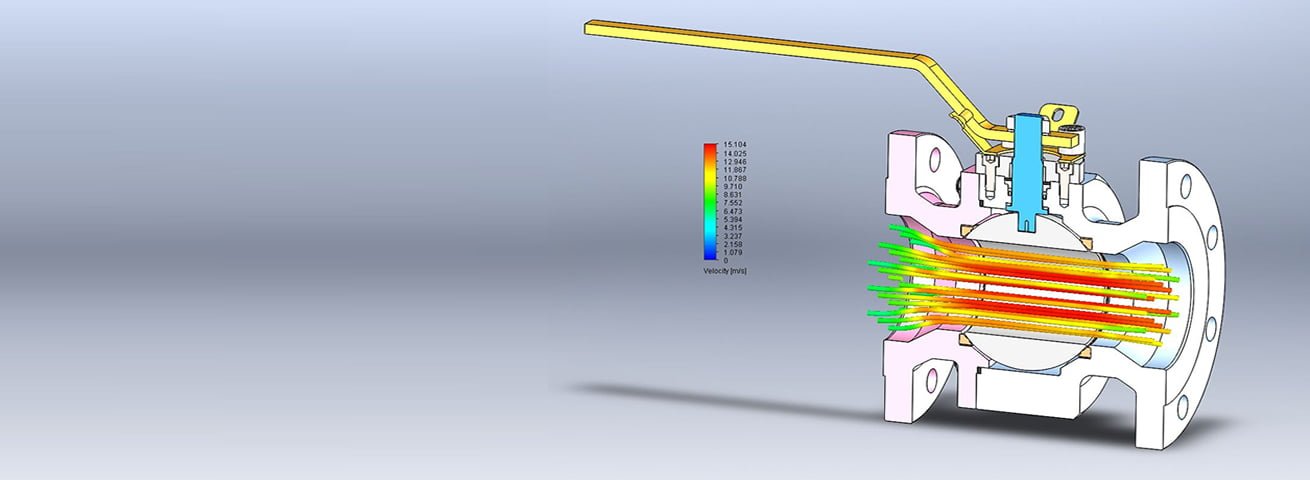

During the engineering design process, some components of the valves are calculated by Finite Element Calculations, as FEA (Finite Element Analysis).

This design tool integrated with the standard calculations (American Society of Mechanical Engineers ASME) provides a further safety factor on the success of the project. A good outcome of the tests enable us to comply with the delivery terms.

This three-dimensional calculation system creates valve body casting calculations enabling the identification of the weakest parts and then strengthen them. Moreover, the system allows the simulation of the valve seal, tightness in the exact point of contact of the ball with the seat, underlining whether deformations lead to a loss of adherence between the surfaces.

Any valve stressed component is assessable by Finite element Analysis.

We can also monitor the flow rate of the valves by quantifying the pressure drop between incoming and outgoing fluid.

The design stages are planned and monitored in the design plans complying with ISO, to be issued at every different request by the Customer.

Moreover, it is Company’s priority any improvement through ongoing studies and researches on new available technologies to reduce the design risks.

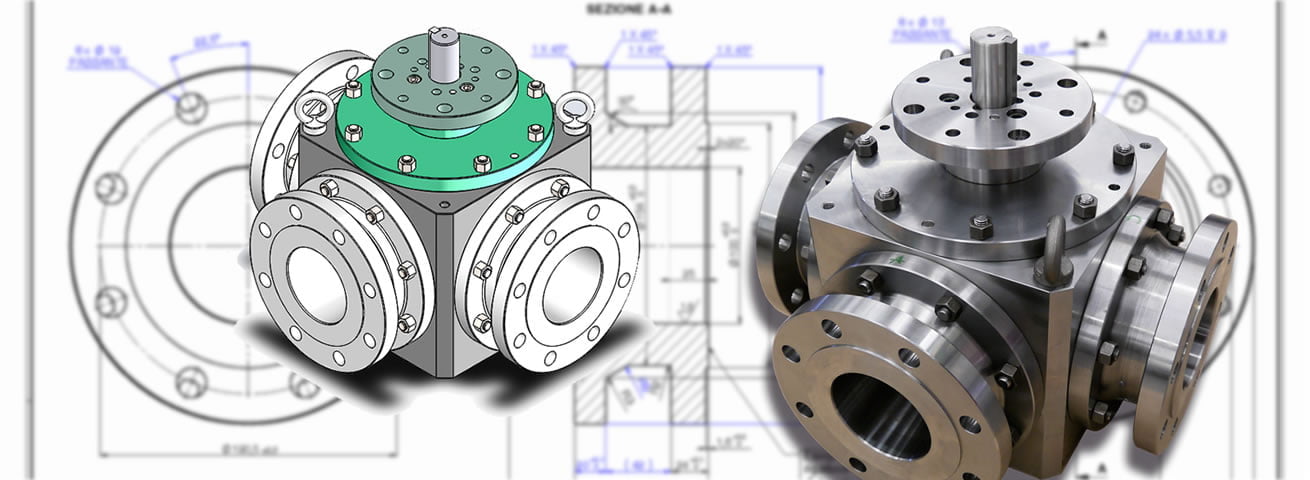

Company ETIOVALVES performs the design process by Softwares as SolidWorks 3D CAD and Simulation for FEA

Standards for the design of the valves are API (American Petroleum Institute) 6D and ASME (American Society of Mechanical Engineers).