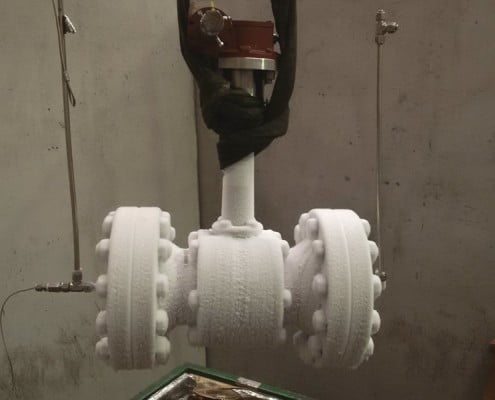

Cryogenic testing of floating / trunnion ball valves

The cryogenic testing is a special testing monitoring any leakage of the valves (for both floating and trunnion mounted ball valves) at any temperature down to -196 ° C (boiling point of liquid nitrogen).

The cryogenic valve is tested according to the operating pressure specified for its class.

It takes a test rig arrangement with a dewar filled with liquid nitrogen , flanged connections and a low cooling period.

It will be our care to agree with the Customer the number of valves to be tested in accordance with their diameter and rate since just a representative samples will be subject to the testing.

Test procedure:

- Slow insulated test dewar with liquid nirogen

- Once the temperature required is reached, the valve is pressurized with helium in compliance with the testing procedure.

- During testing, any atmospeheric leakage is detected and measured by a gas detector (i.e. Sniffer).

- Any internal leakage is measured with a manometer and a bubble leak detector.

- Measurement of cycle time tests at a cryogenic temperature is carried out by a thermocouple inside the valve which displays the exact degrees in C.

- At the end of the testing, a report will be issued. The valve is depressurized and warmed-up until ambient temperature.